Small Diameter Furnace Graphite Electrode ya ng'anjo yamagetsi yamagetsi yazitsulo ndi mafakitale

Technical Parameter

Tchati 1:Technical Parameter For Small Diameter Graphite Electrode

| Diameter | Gawo | Kukaniza | Flexural Mphamvu | Young Modulus | Kuchulukana | CTE | Phulusa | |

| Inchi | mm | μΩ m | MPa | GPA | g/cm3 | × 10 pa-6/℃ | % | |

| 3 | 75 | Electrode | 7.5-8.5 | ≥9.0 | ≤9.3 | 1.55-1.64 | ≤2.4 | ≤0.3 |

| Nipple | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

| 4 | 100 | Electrode | 7.5-8.5 | ≥9.0 | ≤9.3 | 1.55-1.64 | ≤2.4 | ≤0.3 |

| Nipple | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

| 6 | 150 | Electrode | 7.5-8.5 | ≥8.5 | ≤9.3 | 1.55-1.63 | ≤2.4 | ≤0.3 |

| Nipple | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

| 8 | 200 | Electrode | 7.5-8.5 | ≥8.5 | ≤9.3 | 1.55-1.63 | ≤2.4 | ≤0.3 |

| Nipple | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

| 9 | 225 | Electrode | 7.5-8.5 | ≥8.5 | ≤9.3 | 1.55-1.63 | ≤2.4 | ≤0.3 |

| Nipple | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

| 10 | 250 | Electrode | 7.5-8.5 | ≥8.5 | ≤9.3 | 1.55-1.63 | ≤2.4 | ≤0.3 |

| Nipple | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

Tchati 2: Kuthekera Kwamakono Kwa Magetsi Ang'onoang'ono a Graphite Electrode

| Diameter | Katundu Wamakono | Kuchulukana Kwamakono | Diameter | Katundu Wamakono | Kuchulukana Kwamakono | ||

| Inchi | mm | A | A/m2 | Inchi | mm | A | A/m2 |

| 3 | 75 | 1000-1400 | 22-31 | 6 | 150 | 3000-4500 | 16-25 |

| 4 | 100 | 1500-2400 | 19-30 | 8 | 200 | 5000-6900 | 15-21 |

| 5 | 130 | 2200-3400 | 17-26 | 10 | 250 | 7000-10000 | 14-20 |

Tchati 3: Kukula kwa Graphite Electrode & Kulekerera Kwa Diameter Yaing'ono Graphite Electrode

| Nominal Diameter | Diameter Yeniyeni(mm) | Utali Wadzina | Kulekerera | |||

| Inchi | mm | Max. | Min. | mm | Inchi | mm |

| 3 | 75 | 77 | 74 | 1000 | 40 | -75 ~ + 50 |

| 4 | 100 | 102 | 99 | 1200 | 48 | -75 ~ + 50 |

| 6 | 150 | 154 | 151 | 1600 | 60 | ± 100 |

| 8 | 200 | 204 | 201 | 1600 | 60 | ± 100 |

| 9 | 225 | 230 | 226 | 1600/1800 | 60/72 | ± 100 |

| 10 | 250 | 256 | 252 | 1600/1800 | 60/72 | ± 100 |

Main Application

- Kusungunuka kwa calcium carbide

- Kupanga Carborundum

- Kusintha kwa Corundum

- Zitsulo zosawerengeka zimasungunuka

- Ferrosilicon chomera chotsutsa

Malangizo Kupereka Ndi Kugwiritsa Ntchito Kwa Graphite Electrodes

1.Chotsani chivundikiro chotetezera cha dzenje latsopano la electrode, fufuzani ngati ulusi mu dzenje la electrode uli wathunthu ndipo ulusi suli wokwanira, funsani akatswiri amisiri kuti mudziwe ngati electrode ingagwiritsidwe ntchito;

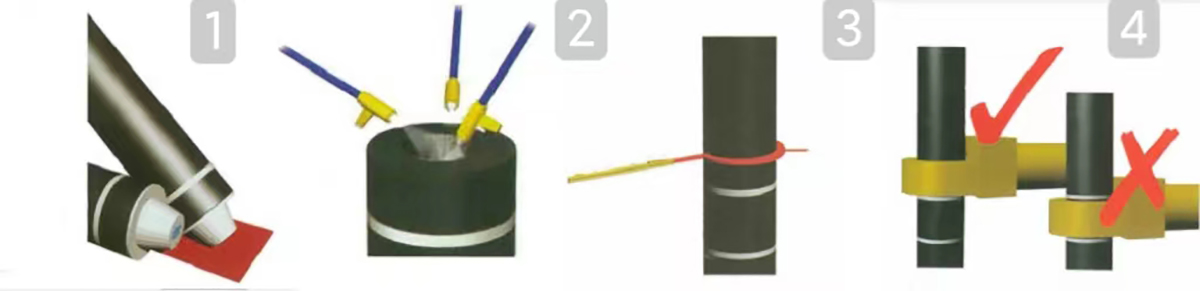

2.Mangani chopachikidwa cha elekitirodi mu dzenje la elekitirodi kumapeto kumodzi, ndikuyika khushoni yofewa pansi pa mbali ina ya elekitirodi kuti musawononge cholumikizira cha elekitirodi;(onani pic1)

3. Gwiritsani ntchito mpweya woponderezedwa kuti muwombe fumbi ndi ma sundries pamwamba ndi dzenje la electrode yolumikiza, ndiyeno yeretsani pamwamba ndi cholumikizira cha electrode yatsopano, yeretsani ndi burashi; (onani pic2)

4.Kwezani electrode yatsopano pamwamba pa electrode yoyembekezera kuti mugwirizane ndi dzenje la electrode ndikugwa pang'onopang'ono;

5.Gwiritsani ntchito torque yoyenera kuti mutseke bwino ma elekitirodi;(onani pic3)

6.Chotengera chotchinga chiyenera kuikidwa kunja kwa mzere wa alamu.(onani pic4)

7.Munthawi yoyenga, ndizosavuta kupanga ma elekitirodi kukhala owonda ndikupangitsa kusweka, kugwa kwa mgwirizano, kuwonjezera kugwiritsa ntchito ma electrode, chonde musagwiritse ntchito ma electrode kuti mukweze kaboni.

8.Chifukwa cha zinthu zosiyanasiyana zopangira zomwe zimagwiritsidwa ntchito ndi wopanga aliyense ndi njira yopangira, thupi ndi mankhwala a electrode ndi zolumikizira za wopanga aliyense. Chifukwa chake mukugwiritsa ntchito, nthawi zambiri, Chonde musaphatikize ma elekitirodi ndi ma olowa omwe amapangidwa ndi opanga osiyanasiyana.