Kachulukidwe Wang'ono Wang'ono Wang'anjo wa Graphite Electrode Wa Ng'anjo Yamoto Ya Ladle Mu Kusungunula Chitsulo

Technical Parameter

Tchati 1:Technical Parameter For Small Diameter Graphite Electrode

| Diameter | Gawo | Kukaniza | Flexural Mphamvu | Young Modulus | Kuchulukana | CTE | Phulusa | |

| Inchi | mm | μΩ m | MPa | GPA | g/cm3 | × 10 pa-6/℃ | % | |

| 3 | 75 | Electrode | 7.5-8.5 | ≥9.0 | ≤9.3 | 1.55-1.64 | ≤2.4 | ≤0.3 |

| Nipple | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

| 4 | 100 | Electrode | 7.5-8.5 | ≥9.0 | ≤9.3 | 1.55-1.64 | ≤2.4 | ≤0.3 |

| Nipple | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

| 6 | 150 | Electrode | 7.5-8.5 | ≥8.5 | ≤9.3 | 1.55-1.63 | ≤2.4 | ≤0.3 |

| Nipple | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

| 8 | 200 | Electrode | 7.5-8.5 | ≥8.5 | ≤9.3 | 1.55-1.63 | ≤2.4 | ≤0.3 |

| Nipple | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

| 9 | 225 | Electrode | 7.5-8.5 | ≥8.5 | ≤9.3 | 1.55-1.63 | ≤2.4 | ≤0.3 |

| Nipple | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

| 10 | 250 | Electrode | 7.5-8.5 | ≥8.5 | ≤9.3 | 1.55-1.63 | ≤2.4 | ≤0.3 |

| Nipple | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

Tchati 2: Kuthekera Kwamakono Kwa Magetsi Ang'onoang'ono a Graphite Electrode

| Diameter | Katundu Wamakono | Kuchulukana Kwamakono | Diameter | Katundu Wamakono | Kuchulukana Kwamakono | ||

| Inchi | mm | A | A/m2 | Inchi | mm | A | A/m2 |

| 3 | 75 | 1000-1400 | 22-31 | 6 | 150 | 3000-4500 | 16-25 |

| 4 | 100 | 1500-2400 | 19-30 | 8 | 200 | 5000-6900 | 15-21 |

| 5 | 130 | 2200-3400 | 17-26 | 10 | 250 | 7000-10000 | 14-20 |

Tchati 3: Kukula kwa Graphite Electrode & Kulekerera Kwa Diameter Yaing'ono Graphite Electrode

| Nominal Diameter | Diameter Yeniyeni(mm) | Utali Wadzina | Kulekerera | |||

| Inchi | mm | Max. | Min. | mm | Inchi | mm |

| 3 | 75 | 77 | 74 | 1000 | 40 | -75 ~ + 50 |

| 4 | 100 | 102 | 99 | 1200 | 48 | -75 ~ + 50 |

| 6 | 150 | 154 | 151 | 1600 | 60 | ± 100 |

| 8 | 200 | 204 | 201 | 1600 | 60 | ± 100 |

| 9 | 225 | 230 | 226 | 1600/1800 | 60/72 | ± 100 |

| 10 | 250 | 256 | 252 | 1600/1800 | 60/72 | ± 100 |

Main Application

- Kusungunuka kwa calcium carbide

- Kupanga Carborundum

- Kusintha kwa Corundum

- Zitsulo zosawerengeka zimasungunuka

- Ferrosilicon chomera chotsutsa

Malangizo Kupereka Ndi Kugwiritsa Ntchito Kwa Graphite Electrodes

1.Gwiritsani ntchito zida zapadera zonyamulira kuti ma elekitirodi a graphite asawonongeke panthawi yamayendedwe.(onani pic1)

2. Graphite electrode iyenera kusungidwa kuti isanyowe kapena kunyowa ndi mvula, chipale chofewa, ikhale yowuma. (onani pic2)

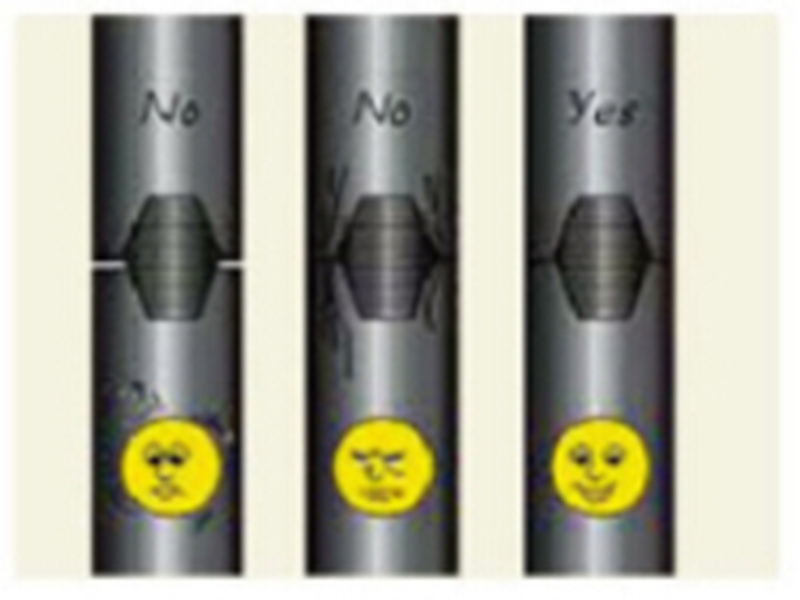

3.Kufufuza mosamala musanagwiritse ntchito onetsetsani kuti socket ndi ulusi wa nipple ndi woyenera kugwiritsidwa ntchito, kuphatikizapo kuyang'anitsitsa phula, pulagi. (onani pic3)

4.Tsukani ulusi wa nipple ndi sockets ndi mpweya woponderezedwa.(onani pic4)

5.Musanayambe kugwiritsa ntchito, electrode ya graphite iyenera kuuma mu ng'anjo, kutentha kwakuya kuyenera kukhala kosakwana 150 ℃, nthawi yowuma iyenera kukhala yoposa 30hours. (onani pic5)

6.Graphite electrode iyenera kulumikizidwa mwamphamvu komanso molunjika ndi torque yoyenera yothina.(onani pic6)

7.Kupewa kusweka kwa ma elekitirodi a graphite, ikani gawo lalikulu pamalo otsika ndi gawo laling'ono pamalo apamwamba.